Trade 'Em On Up

When it comes to planters, Bill has always had the latest and greatest. Trading in and buying new every 5 years has ensured his planter systems and technology don't get worn out. It’s also given Bill the opportunity to try a variety of brands. His last planter was a 24-row Kinze 4900 and the one before that was a 24-row John Deere ExactEmerge 1775NT CCS. Buying new every 5 years means Bill has really stayed up on new planter advancements straight out of the factory.

A Purchase with a Purpose

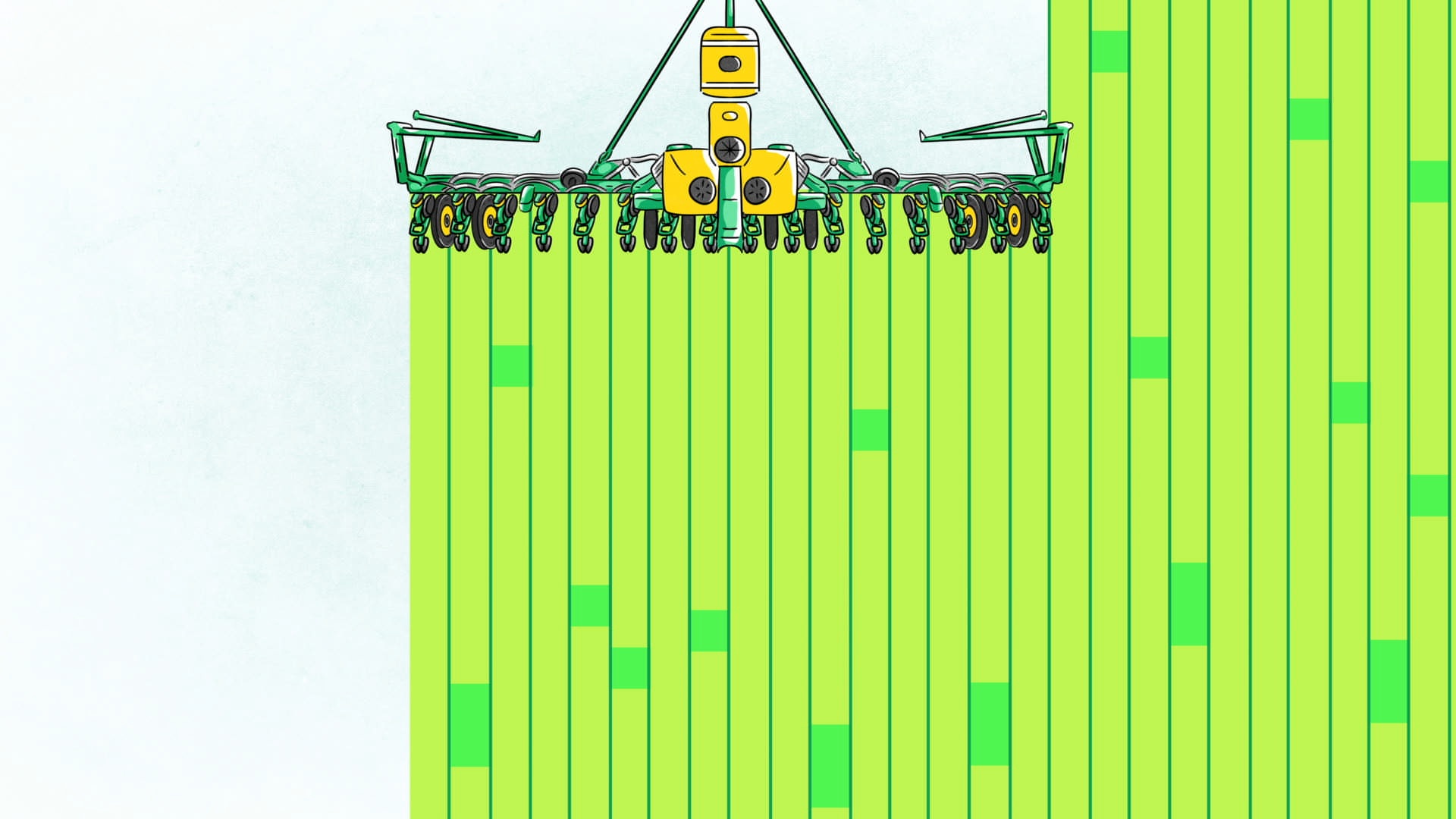

Over the years, Bill has learned to work smarter, not harder. When he hit the 5-year trade-in mark on his Kinze, Bill decided to go with a new 24-row Case IH 2150, equipped with a whole host of Precision Planting technology:

- vDrive » Individual Row Electric Drive Metering1

- vSet » Seed Meter Singulation1

- DeltaForce » Automated Downforce Control2

- SpeedTube » High Speed Planting2

- 20|20 » Visualize data in the cab2

At the time of purchase, Bill was pleased to know that his planter was equipped with Precision Planting technology from the factory, but he didn’t grasp the full extent to which it would impact his planter’s performance and ultimately his yields. Bill also chose to add a 20|20 to his planter build, knowing it would give him visibility to his planter like he’s never seen before.

Bill's dealer helped him get up-to-speed on how to operate the 20|20 and be sure all of his systems were calibrated correctly. He learned through a phone conversation that the 20|20 Planter Base System is the foundation on which many more products are built, with a variety of additional upgrades available that add increased efficiency and performance.

When planting rolled around, Bill was ready to go and able to see all of his real-time data. With Precision Planting technology, he saw a huge difference in the accuracy, quality, and stand of his crop, more than ever before in the tough clay of his no-till operation.

With automated downforce, electric drive and high speed, his new planter has taken his operation to a whole new level and has so much more potential.

5 Years Down the Road

Planters come and planters go, but Bill’s Case IH is here to stay. Because of his initial investment in the 20|20 Planter Base System, he’s had the opportunity to upgrade year over year with recommendations from his local Precision Planting Premier Dealer3.

Instead of trading for another new planter, Bill decided to upgrade to FurrowForce, Reveal, and vApplyHD, taking it from satisfactory to exceptional.

» FurrowForce

No-tilling in tough clay, Bill had tried some aggressive wheels a few years past and decided this time to go with a whole new system. FurrowForce isn’t your typical 2-stage closing system; it adapts to planting conditions to remove air pockets and firm soil to retain moisture. This upgrade gave Bill confidence that his crops would germinate as best they could.

Stage 1: notched wheels close the seed furrow from the bottom up, fracturing to eliminate air pockets, even in extreme no-till conditions.

Stage 2: stitch wheels carry weight on them to firm the soil during spring tillage where the seed environment can dry out.

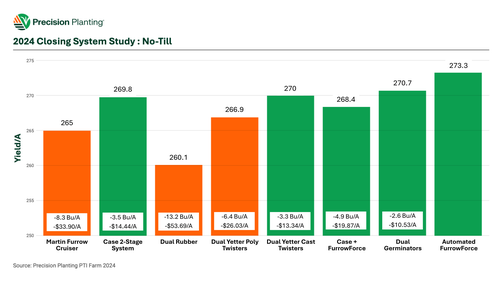

The Research

In our 2024 no-till corn closing wheel study at the Precision Technology Institute, the Case 2-stage system experienced an 8.3 Bu/A. yield loss compared to the automated FurrowForce system.

FurrowForce outperformed all closing systems with yield gains of 2.6 Bu/A. to 13.2 Bu/A.

» Reveal

Bill installed Reveal frame-mounted row cleaners to eliminate the negative effects of row-unit chatter and downforce that he experienced with his original row cleaners.

With Reveal, Bill can set the pressure needed to keep the no-till coulter in the ground to eliminate bounce and also adjust the depth of the cleaning tines to create a consistently clean and ideal seeding environment for even emergence to occur. He can also adjust airbag pressure with his 20|20 to maintain a consistent depth.

» vApplyHD

For Bill, the next step was liquid control to gain more consistent application rates. vApplyHD uses a pump control module and then control modules on the toolbar. The modules on the toolbar control flow, measure flow, and swath all in a single device.

With vApplyHD, he can utilize row-by-row rate and swath control, liquid prescriptions and turn compensation to apply the correct rate at every point in the field while staying aware of his rate with the 20|20 monitor.

» FurrowJet: the Perfect Pair

Placement of the fertilizer in the furrow is just as critical as the rate at which it is applied.

With the combination of vApplyHD and FurrowJet, Bill knows the exact amount of fertilizer being applied to each plant and the precise location of it as well. With FurrowJet, he can choose the exact placement, whether through the center of the firmer, 3/4" away from the seed on either side, or in all 3 of these locations.

What's Next for Bill?

The combination of these upgrades has given Bill confidence in his planter and its performance across all fields and all soil types to clean, close, and distribute fertilizer precisely in the furrow.

5 more years? His planter’s STILL here to stay, and his yields continue to blow him away.

These upgrades are next on his list:

SmartFirmer » Seed firmer and moisture sensor

SmartDepth » On-the-go depth adjustment

Working Together: SmartFirmer measures the moisture available to the seed, sends feedback to the 20|20, and SmartDepth automatically adjusts the planting depth, ensuring that seeds are planted in adequate moisture.

1 Product comes standard from the CaseIH factory.

2 Product is optional and can be added on at the CaseIH factory.

3 Product availability varies from dealer to dealer. Please check with your CaseIH dealer upon ordering your planter to see what options are available. Additional products can be added through a local Precision Planting dealer in your area. See all of our OEM guides for more upgrade information.