It wasn’t too long ago that the greatest advancement made for sprayers was a rate controller with manual section valves. From there, automatic section valves were introduced and greatly improved the efficiency of the spraying workflow as they reduced fatigue on the operator as well as the total overlap of chemicals.

It’s safe to say the agriculture industry has come a long way in terms of the technology available for sprayers in a short time. Thankfully, the advancements keep coming.

SymphonyVision takes weed control to the next level. This vision-based spray system uses intelligent cameras to adjust application rate based on weed severity, maximizing both chemical and cost savings.

The Value of Weed Severity

Weed severity, a metric unique to Precision Planting, combines both weed size and weed density. While spraying with SymphonyVision, a higher weed severity value equates to a higher rate of application whereas rates will drop in areas of the field where weed severity is lower.

The application rates the system uses are defined by the user. As the operator, you can decide what rate to use for the differing levels of weed severity – none, low, medium, and high. The ability to adjust rates to values you are comfortable with and confident in gives you complete control over the spraying workflow.

High weed severity is not only associated with large weeds that are further along in their lifecycle. A dense population of small weeds that overlap may not see the full rate during application and as a result require a higher rate to see a complete kill. By taking both the number of weeds and their size into consideration, the SymphonyVision system can better determine the rate needed to effectively control the weed population.

Setting the Foundation with SymphonyNozzle

SymphonyNozzle, a foundational element to SymphonyVision, is a pulse width modulation system (PWM), giving you independent control of both rate and pressure. This functionality enables the sprayer to keep boom pressure consistent regardless of changes in speed. As a result, uniform droplet sizes are created throughout the spraying workflow.

Additionally, each nozzle operates independently from the next, allowing for nozzle-by-nozzle swath control. Instead of waiting to turn off the entire boom valve section as you approach an area that has already been sprayed or come to a boundary, nozzles will turn off individually.

SymphonyNozzle not only delivers uniform rates across the boom, but it also mitigates the potential yield penalty that can come from sprayer overlap.

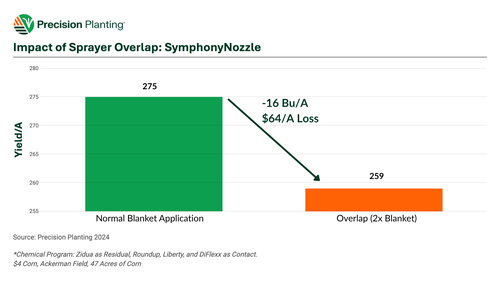

A 2024 Precision Planting trial tested the impact of sprayer overlap on corn yield.

The acres that received a normal blanket rate yielded 275 Bu/A. Where the sprayer overlapped and double the blanket rate was applied, the crop yielded only 259 Bu/A, resulting in a 16 Bu/A ($64/A) yield loss and wasted chemicals.

About SymphonyVision | Rate

One common issue with weed control today is that you must treat the entire field the same even if weed pressure across the field is drastically different. Areas of the field that may have little to no weeds are receiving the same amount of chemical as areas experiencing high weed pressure. This results in wasted chemicals and is ultimately lowering your return on investment.

With SymphonyVision | Rate, you’re no longer conducting a blanket application. Instead, the system adjusts rate depending on the weed severity present at each point in the field. Throughout the spraying workflow, the boom is continuously on, and rate is adjusted on an individual nozzle basis automatically to increase or decrease rate accordingly.

Compatible with a single mix of contact and residual herbicides, SymphonyVision | Rate allows you to vary the rate of both coming from the same tank. In doing so, you can achieve better weed control in the problem areas and experience savings in the areas with low weed pressure.

SymphonyVision | Rate requires the placement of one camera every 10 feet across the boom and is equipped with the technology and database needed for corn, soybean and cotton spraying applications.

SymphonyVision | Rate in Action

About SymphonyVision | Spot

SymphonyVision | Spot allows you to achieve even greater cost savings as it automatically turns nozzles on and off during application while also adjusting the rate of the nozzles that are spraying.

If no weeds are detected, the nozzles remain off. Once a weed is detected by the camera, the nozzles turn on to spray that specific weed. Maximum chemical savings means greater cost savings. The number of nozzles that spray once a weed is detected is customizable by the user, however, the recommended setting is a three-nozzle minimum.

SymphonyVision | Spot requires the placement of one camera every five feet across the boom and is equipped with the technology and database needed for corn, soybean and cotton spraying applications.

SymphonyVision | Spot in Action

About SymphonyVision | Duo

Precision Planting’s latest addition to the SymphonyVision family, SymphonyVision | Duo, takes precision spot spraying to the next level. Duo is a dual nozzle system, meaning you can spot-spray contact herbicides based on weed severity while simultaneously broadcasting residuals, fertilizers or fungicides all in the same pass.

The bulk tank on the sprayer houses the primary tank mix (residual, fertilizer or fungicide), while separate concentrate tanks carry the contact herbicide. The onboard injection system mixes solution from the bulk tank with the additional contacts on the go, preventing you from having to manage two separate tank mixes.

SymphonyVision | Duo leverages all SymphonyVision | Spot components (vision cameras) and a 20|20 monitor as well as an injection pump, mixer and a second set of Symphony nozzles. The system is equipped with the technology and database needed for corn, soybean and cotton spraying applications.

Gain more control over your sprayer than ever before while reducing your chemical costs and environmental impact with SymphonyVision | Duo.

SymphonyVision | Duo in Action

Key Takeaways

SymphonyVision systems can take your chemical weed control program to the next level and allow you to experience cost savings without sacrificing weed control. Which system is right for your chemical weed control program ultimately depends on your needs and budget. Here's a few key takeaways to help you determine the best fit for your operation:

- The number of cameras needed is based on the length of the boom and desired capabilities.

- SymphonyVision | Rate has the lowest cost as it requires the fewest cameras.

- SymphonyVision | Spot and SymphonyVision | Duo can turn nozzles completely off whereas SymphonyVision | Rate can only adjust the rate while leaving the cameras on.

- SymphonyVision | Duo offers the premiere experience, enabling both spot spraying and broadcast application in the same pass.

- SymphonyVision | Rate and SymphonyVision | Spot can both be upgraded to SymphonyVision | Duo by adding additional hardware components.