Scott Van Etten, Product Specialist, conducted a spraying demonstration at Winter Conference 2025 using a two-nozzle sprayer stand to showcase the effects nozzle selection has on sprayer performance.

Learn about the results below ↓

Your sprayer makes more passes over the crop than any other piece of equipment throughout the growing season and getting it operating at its peak performance is critical to protect the health of your crops.

To achieve the weed control you're after, your sprayer must do two things exceptionally well:

- Achieve the desired rate of application

- Apply the correct coverage

As the operator, one component you can optimize that directly impacts how well your sprayer achieves the correct rate and coverage is the spray nozzles. But with hundreds of options available on the market, how do you know if you’re using the right nozzles for your operation?

When selecting your nozzles, you must consider a variety of attributes like nozzle style, spray coverage and spray quality, and how they align with the recommendations on your chemical labels.

Impact of Nozzle Style on Spray Coverage

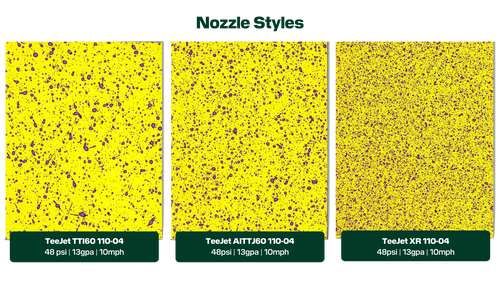

To better explain the impact nozzle style has on spray coverage, the following demo was completed with three different nozzles, each of which sprayed a pass at the same rate, speed, and pressure (13 gal/A, 12 mph, and 48 psi). For consistency, each of the nozzles utilized in the demo were TeeJet nozzles but similar results can be expected across all brands.

When analyzing spray cards, two metrics that indicate ineffective coverage are large droplet marks and measurable gaps between droplets.

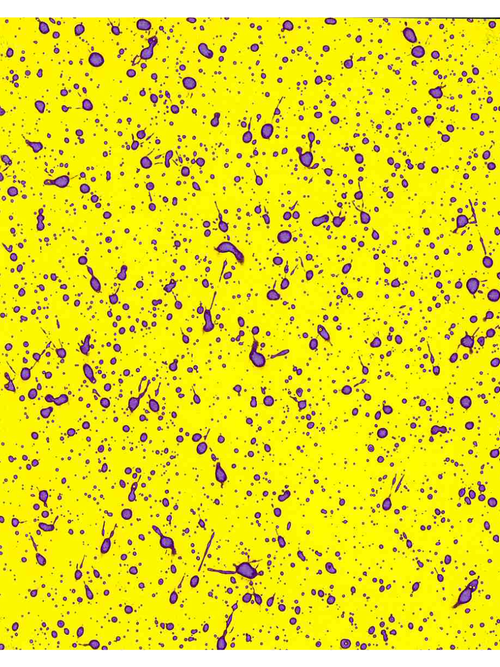

TTI60 110-04

The first card was sprayed with the TTI60 110-04 nozzle. After application, several large droplets are visible which are a concern because they travel at a higher velocity, causing them to rebound and explode when they make contact with the plant leaf instead of staying on the target.

Additionally, when large droplets are present, they consume more of the spray volume often leading to gaps in coverage. Gaps in coverage open the opportunity for weeds to escape your chemical weed control program.

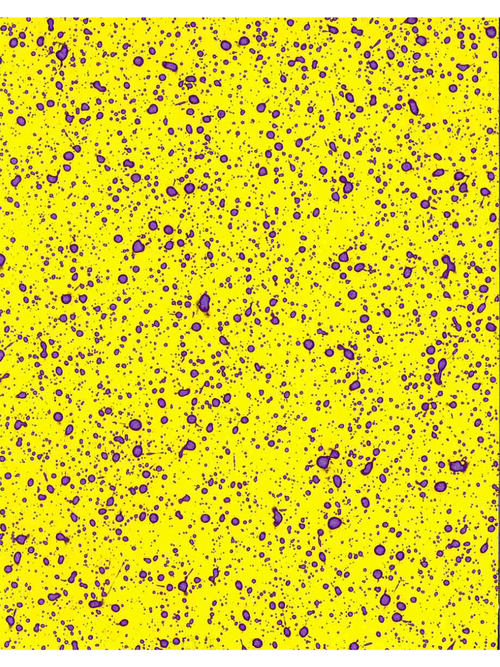

XR 110-04

The second card was sprayed with an XR 110-04, flat fan spray nozzle, commonly known as an extended range nozzle. Sprayed at the same rate and speed as the first nozzle, no large droplets or gaps in coverage are present on the spray card.

The spray plume created by this nozzle consisted of purely small droplets which resulted in the most complete coverage of the spray card in terms of surface area.

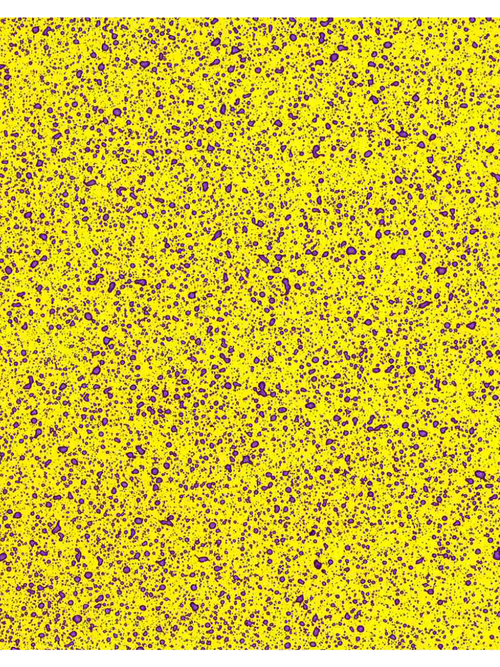

AITTJ60 110-04

The final card was sprayed with an AITTJ60 110-04 nozzle. When applied at the same rate and speed as the first two passes, some larger droplets are noticeable, however, enough smaller droplets are present to provide adequate coverage.

Compared to both the TTI60 110-04 and XR 110-04 nozzles, there is a much greater diversity in droplet size ranging from small to large droplets.

Although the XR nozzle gave us the most complete coverage, we have a much higher risk of drift. In the controlled environment the demo was completed in, no external factors prevented the droplets from the XR nozzle from making their way down to the spray card. However, field conditions introduce environmental factors such as wind, temperature, and humidity. Those small droplets may evaporate before ever reaching the plant or drift off-target to areas outside of the field.

When considering droplet size while selecting your nozzles, you must balance drift control with gaps in coverage. For this application, it appears the AITTJ60 nozzle may yield the best coverage while limiting drift.

With all three nozzles, the 20 | 20 tells us that each pass was applied at the same exact rate, 13 gal/A. However, that doesn’t account for the spray coverage. All three nozzles applied the same rate, but the spray coverage varied drastically.

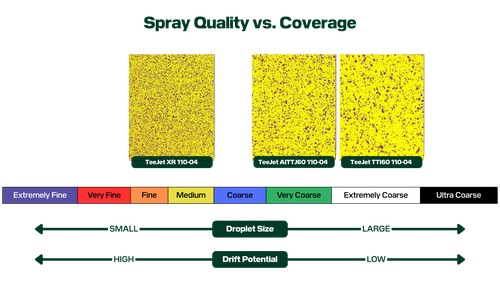

Spray Quality vs. Coverage

A metric used to compare one nozzle to the next is spray quality. Manufacturers use spray quality to categorize nozzles based on the median diameter of droplet size the nozzle produces.

It’s important to remember that just because a nozzle falls into a certain category, that doesn’t mean it is only producing that one size of droplet as we saw in the above spray cards. 50% of the droplets will measure smaller than the median value and 50% of droplets will measure larger than the median value, so it’s important to find the balance that works best for your application.

As we compare the three nozzles used in the demo, the XR nozzle with the smaller droplets comes in at the fine end of the spectrum, whereas the other two fall between very coarse and extremely coarse.

Fine droplets, like those created by the XR nozzle may increase coverage but also increase your risk of drift. Nozzles that fall in the coarse categories, like the AITTJ60 and TTI60 produce larger droplets and, in return, lower your risk of drift. However, large droplets increase your risk of incomplete coverage by potentially creating measurable gaps that allow for weed escapes.

To learn the spray quality recommended for your application, check the chemical label as it will indicate the correct droplet size for that chemical. For example, according to a 2,4-D label, if it is the sole ingredient in your tank, it should be applied only as a coarse or coarser spray.

Although there are still plenty of options to choose from, the chemical label will help you to narrow your search.

Impact of Pressure on Spray Quality

A traditional sprayer aims to keep the desired rate that you as the operator set.

When you speed up or slow down, the flow through the sprayer changes. As speed increases, the flow also increases to maintain the consistent rate, causing the pressure to increase. An inverse effect takes place as speed decreases. As you slow down, the flow decreases, causing the pressure to also decrease.

How does this change in pressure impact spray quality?

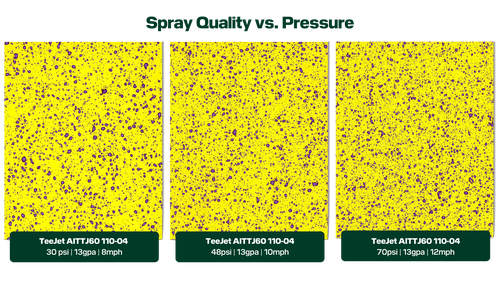

Using the AITTJ60 card that was sprayed earlier at 10 mph and 48 psi, let’s compare it to cards sprayed at both increased and decreased speeds to understand the implications of a change in pressure.

Let’s say you need to slow down to 8 mph as you approach a corner or slow down for a washout in the field. A speed of 8 mph led to a decrease in pressure to 30 psi, resulting in larger droplets and changing the spray quality from coarse to very coarse.

As you get out into the middle of the field, you ramp things up to 12 mph. The pass completed at 10 mph had a pressure of 48 psi whereas the 12 mph pass had a pressure of 70 psi. This relatively small change in speed led to a 22 psi increase. The change in pressure resulted in smaller droplets, changing the spray quality from very coarse to coarse. When in the field this may cause increased drifting off target.

Unfortunately, even the most careful and cautious operators can’t adjust for the impact of speed changes when using a traditional rate control system. So, what can you do?

Keep Pressure Consistent with SymphonyNozzle

SymphonyNozzle, a pulse width modulation system, gives you independent control of rate and pressure. This allows you to not only maintain the desired rate of application, but also keep your pressure consistent, regardless of speed changes. With SymphonyNozzle, you have a much wider operating range, which enables you to continuously hit your targeted spray quality even with a change in speed.

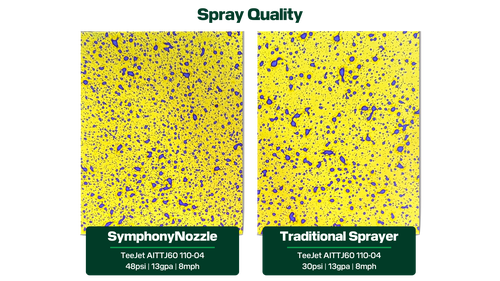

Let’s take a look at how a SymphonyNozzle system paired with an AITTJ60 nozzle compares to a standard sprayer with the same AITTJ60 nozzle.

With SymphonyNozzle installed, the system achieved a pressure of 48 psi running at 8 mph, resulting in a more consistent spray quality and ultimately improving our coverage. Compared to the standard application with the AITTJ60 nozzle where larger droplets make up more of the spray volume and spaces between those droplets are present.

It’s important to note – when selecting nozzles for a PWM system, they should be 30-50% larger than those on a standard sprayer. This gives the sprayer a wider operating range and the ability to perform consistently at significant speed changes.

The SymphonyNozzle system is compatible with multiple boom sizes and can be installed on both self-propelled and pull-type sprayers. Upgrade your system without switching sprayers and improve the consistency of your spray quality with SymphonyNozzle.

Precision Planting is a worldwide brand of Precision Planting LLC © (2025) Precision Planting LLC. PTx and the Associated Logo are worldwide brands of AGCO Corporation. All product names and brands are the property of their respective owners. All company, product and service names used are for identification purposes only. Use of these names and brands does not imply endorsement. Other names or logos, such as TeeJet, may be trademarks of their respective owners.