Picture this.

You sit down after harvest and begin planning your chemical weed control program for the upcoming season. You consider what worked well last year, account for what didn’t, and eventually arrive at your tentative plan – Dual Magnum, Callisto, Atrazine, and Roundup.

Fast forward a few months and it’s just about time to take your sprayer to the field to implement the plan you crafted in the off season. Before doing so, you go scout to ensure the program you planned will provide you with the effective weed control needed to prevent costly weed escapes in your fields. While scouting, you take note of the types of weeds present as well as the size and density of those weeds. This information will help you determine the application rate of the chemicals within your program.

As you scout the first field, you find that roughly 25% of the scouted area consists of only small weeds and around 75% of the area is clean and presents no weed pressure. However, it's a much different story in one corner of the field. Here, you find a high volume of small weeds and many areas in which they overlap. The final area scouted consisted of heavy Waterhemp pressure, some measuring up to six inches tall. A finding you weren’t expecting and certainly not one you planned for when mapping out your chemical weed control program prior to the season.

You begin to second guess if the chemical program you originally designed will be able to handle the dense weed populations and eliminate the large Waterhemp plants present in the field, so you consider your options.

- Choose to apply at the low end of the application range. This would be adequate for the areas of the field with small weeds and ultimately allow you to save on input costs. Although this is the most cost-effective option, it will likely leave several weeds in the field.

- Apply the high label rate to target the areas with dense weed populations and hopefully eliminate a majority of the Waterhemp in the process. Although this should yield better weed control, it will increase your input costs significantly. A blanket application at the high chemical rate with your current program will cost you an additional $12/A. In this 100-acre field alone, that’s an increase of $1,200.

- There’s a risk that even the high label rate of the chemicals currently in your program may not be enough for the large Waterhemp plants. You can choose to add an additional mode of action to your program, one that specifically targets Waterhemp measuring six inches or greater. This route will surely provide you with the most effective weed control, but is the additional cost of another mode of action worth it?

It’s a tough decision to make. You know the risk of weed escapes and want to ensure you eliminate the problem in year one so you don’t continue to battle this Waterhemp issue in the years to come, but adding an additional mode of action to target the small percentage of the field that needs it certainly won’t be good on your bottom line.

What if there were a way to combine these three options and save on costs without sacrificing weed control?

Lucky for you, there is, and the Precision Planting team has already tested it to show you the results.

Real Acres, Real Results

The above scenario is based upon an actual field (Terhune) farmed by Precision Planting’s Research & Development team for product testing purposes.

When it came time for the team to decide between the options regarding the application rate, it wasn’t a tough decision at all — they could variable rate the chemical with a SymphonyVision system.

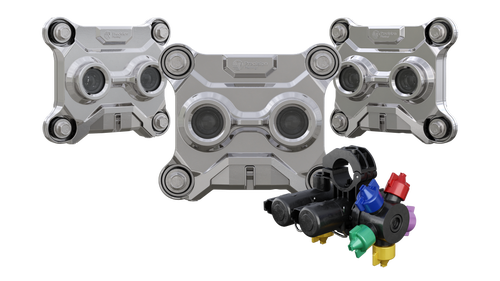

SymphonyVision | Rate, SymphonyVision | Spot and SymphonyVision | Duo all utilize intelligent cameras to apply chemicals via live variable rate application. Meaning, the rate is adjusted as weed pressure changes across the field. The system utilizes weed severity to vary the rate of each nozzle automatically while continuously spraying.

Weed severity, a metric unique to Precision Planting, takes both weed size and weed density into account to determine the rate needed to achieve an effective kill.

Impact of SymphonyVision | Rate on the Terhune Field

Instead of blanket applying the high label rate to target the small percentage of the field that needed it, SymphonyVision | Rate varied the application rate from low to high according to the weed severity present.

In the areas with only small, sparse weeds or no weeds at all, the low chemical rate was applied1 as those areas were categorized as low weed severity. Areas with large weeds received the high chemical rate1 as they fell into the high weed severity bucket. Areas with a high density of weeds were also categorized as high weed severity since those weeds often overlap and require more chemical for a complete kill to take place.

Chemical and Cost Savings

It was ultimately decided that an additional mode of action was needed as none of the chemicals originally planned for use in the chemical program were rated to tackle the large Waterhemp plants. As a result, DiFlexx was added to the tank mix, a costly but necessary addition to eliminate the Waterhemp issue.

With Dual Magnum, Callisto, Atrazine, Roundup, and DiFlexx in the tank, it cost $42/A to apply the low rate, $49/A to apply the medium rate, and $56/A to apply the high rate.

The following weed severity map from Panorama created by 20|20 data shows the breakdown of acres based on weed severity and the rate applied.

Of the 100-acre field, 97.5 acres received the low chemical rate, 1.5 acres received the medium rate, and only one acre received the high rate.

The results? A clean field and an average cost per acre of $42.30. Meaning, it only cost an additional $0.30/A for the high label rate to be applied on the weeds that needed it versus blanket applying the low label rate at $42/A.

Had DiFlexx not been added, it would have cost $39/A to blanket the high label rate. It originally cost $17/A to add DiFlexx to the tank mix, but with SymphonyVision | Rate it only cost $3.30/A. For only a few dollars an acre, the risk of a Waterhemp weed escape was eliminated.

It would have been possible to achieve the same weed control without SymphonyVision | Rate, however, blanket applying the tank mix at the high label rate would have cost $56/A. SymphonyVision | Rate resulted in a $14/A input cost savings without sacrificing weed control. That’s $1,400 saved in this 100-acre field alone.

Improve Your Bottom Line

No matter the field, if there is any variation in the weed pressure, SymphonyVision | Rate will do one of two things:

- Increase your weed control for roughly the same cost.

- Keep your weed control the same and save you money.

If you take the above example and expand it out over 1500 acres of corn, it will cost the farm $21,000 in wasted chemical if only a blanket application was applied. But that’s not the only place SymphonyVision saves on costs.

SymphonyNozzle, a foundational element of the SymphonyVision system, prevents overlap during application. Let’s say you have a corn chemical cost of $45/A, soybean chemical cost of $65/A, and an average overlap of 4%. On a 3000-acre farm, the result is $6,600 in wasted chemical and $4,440 saved by preventing the yield penalty caused by sprayer overlap.

There’s $32,000 worth of opportunity between the input savings on both the corn and soybean chemical programs and potential yield recovery.

What could you do with an extra $32,000 in your pocket at the end of next season?

Cost Saving Options

Variable rate application with SymphonyVision | Rate, SymphonyVision | Spot or SymphonyVison | Duo allow you to lessen the amount of chemical applied and reduce input costs without sacrificing weed control, a win for both the environment and your bottom line.

What makes Symphony Vision | Spot different than Rate? You can turn nozzles off entirely to spot spray and reduce your chemical input even more.

Interested in broadcast and spot spraying in the same sprayer pass? SymphonyVision | Duo is a dual nozzle system, meaning you can spot-spray contact herbicides based on weed severity while simultaneously broadcasting residuals, fertilizers or fungicides all in the same pass.

Reach out to your Precision Planting Premier Dealer to replicate the above scenario on your farm with your acres and learn about the specific cost savings you can experience with SymphonyVision products.

SymphonyVision | Spot

SymphonyVision | Spot uses cameras to detect weed severity, automatically adjusting the rate of each nozzle when weeds are present and turning off nozzles when they aren't. Suggested camera spacing is 5 feet.

SymphonyVision | Duo

SymphonyVision | Duo allows contact herbicides to be spot-sprayed while residuals, fertilizers or fungicides are broadcast applied all in a single pass, based on what the cameras on the sprayer see. Suggested camera spacing is 5 feet.

1 Disclaimer: Always read and follow label instructions and consult your chemical representative if you have questions.

Precision Planting is a worldwide brand of Precision Planting LLC © (2025) Precision Planting LLC. PTx and the Associated Logo are worldwide brands of AGCO Corporation. All product names and brands are the property of their respective owners. All company, product and service names used are for identification purposes only. Use of these names and brands does not imply endorsement. Other names or logos, such as Atrazine, Callisto, DiFlexx, Dual Magnum and Roundup, may be trademarks of their respective owners.