Key Points

With a few component upgrades, you can customize your planter to fit your exact needs and even adapt to varying conditions across your fields.

- Metering & Drive

- Downforce

- High-Speed Planting

- Data Visualization

Your Planter Wasn’t Designed for Your Fields

Your stock factory planter should be capable of creating a nearly perfect stand. Unfortunately, it was designed for the average field (not your fields), which means average profitability. Your tillage practices, fertility program, and soil variances are much different from your neighbors’. So why should your planters be equipped the same? We’re here to change that.

With a few component upgrades, you can customize your planter to fit your exact needs and even adapt to varying conditions across your fields. We have a few suggestions for how to save time and increase your profitability.

Metering & Drive

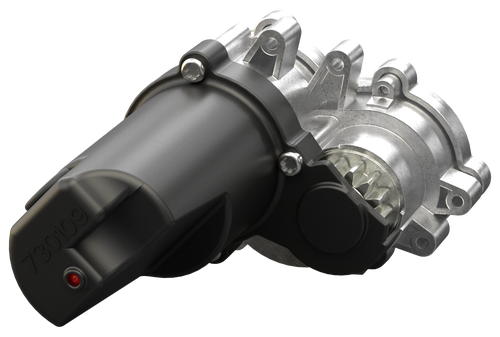

Traditional seed meters need continual adjustment to plant accurately which leads to skips, doubles, and ultimately, lost yield. vSet seed meters singulate seeds accurately without any adjustments resulting in perfect seed placement throughout your field.

vSet meters are compatible with a ground drive or hydraulic drive system and are a great entry point to upgrading your existing vacuum meters. To further enhance your planter, consider adding a vDrive motor to each meter for even greater seeding accuracy.

On a 16-row planter, there are at least 216 parts that make up a traditional ground drive system. That’s a lot of bearings, sprockets, chains, idlers, and tensioners that could go bad and need to be maintained every year. Even with good maintenance, there are still issues that can come up during planting.

vDrive is a low-maintenance, electric drive system that lets you breeze through planting without the headaches of a mechanical drive system. Go from 13 parts to just 1, simplifying your planter. Through a 20|20 monitor you can visualize the health of each individual vDrive motor, giving you peace of mind that each row is running at its best.

With the vSet meter and vDrive motor combined, prepare to save on inputs and prevent overplanting.

Downforce

Is the downforce on your planter relying on springs or airbags? What happens when your seed hopper is empty or when you experience planting in different soil conditions? Nothing happens unless it’s manually changed. Your springs will stay in the same position, or your airbags will stay right where you set them. This results in uneven ground contact and seed placement.

DeltaForce is an automated row-by-row downforce control system that measures and adjusts downforce every time there is variability in your field, improving emergence and giving you ultimate control. And you can add it to your current planter.

In one pass with the planter, we can go through four different zones of soil types, that all need to be treated differently. The power of DeltaForce is that it automatically adjusts down force pressure according to the needs of each row, which are vastly different. Adding DeltaForce to our corn planter has been our biggest and fastest return on investment.

Nathan Ring

Farmer & Dealer | Central Illinois

High-Speed Planting

Every season there’s an optimum planting window. Have you ever been in the position where you couldn’t get all your acres planted quick enough and you had to settle for planting in less-than-ideal conditions? We believe you shouldn’t have to sacrifice yield potential because you can’t get enough acres in the ground when the weather is perfect. You also shouldn’t have to spend more money on a bigger planter or additional planters to make it happen.

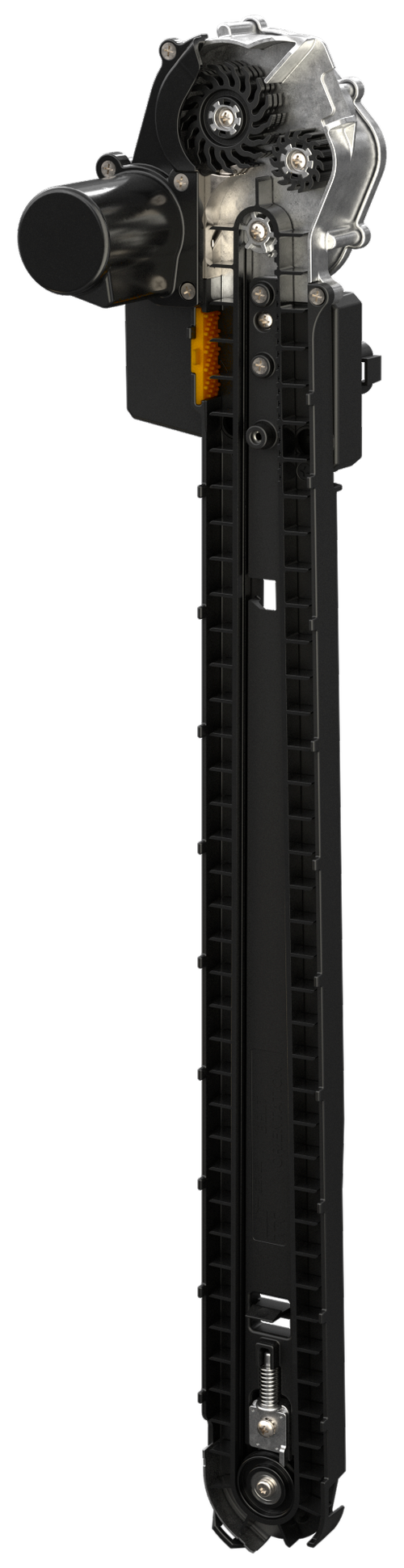

SpeedTube guides seeds from the vSet meter to the seed trench, within a flighted belt, ensuring consistent placement and singulation. Proper seed delivery gives you the power to plant faster, saving you time and optimizing windows of good weather.

When farmers add SpeedTube to their existing planter, they’ve nearly doubled their planting speed without sacrificing performance.

We were able to increase the acres we cover per hour by 40% and not give up any performance. In one day, we planted 400 acres with our 16-row planter before the rain came.

Grant Hannah

Farmer | Illinois

Visualizing the Data

As you look for ways to increase profitability next season, remember that improving your planter performance is one of the quickest returns on investment you can make to your farming operation. But you cannot change what you cannot see.

Let the 20|20 system lead you to better decisions as it monitors, controls, and diagnoses your field conditions and equipment performance. The Gen 3 20|20 monitor provides the most advanced agronomic picture you’ve ever seen, showing high-definition data that fuels high-impact decisions. It can be utilized as a monitor to help you set the planter and power the performance systems listed above.

Not only does it give you accurate data in real-time, but it also gives your equipment the powerful automation to make decisions as it passes through the field, optimizing every pass. The 20|20 gives you the knowledge that you need to maximize the success of your equipment, your crops, and your farm.