Key Points

- Real Results: The FurrowForce two-stage manual closing system resulted in average yield gains of +3.9 Bu/A and additional revenue of +$16.31/A across all tillage environments.

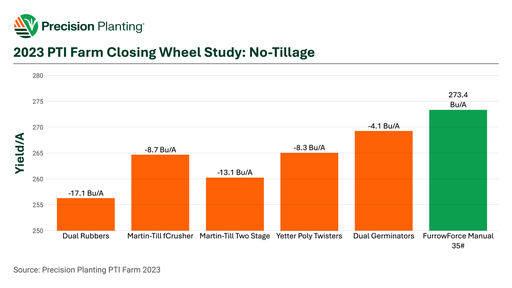

- No-Till Advantage: Study results indicate that in tougher closing situations, a more robust system is needed to effectively close the furrow.

- The Difference: Automated FurrowForce outperformed all other closing wheel systems in every tillage environment.

C is for Close

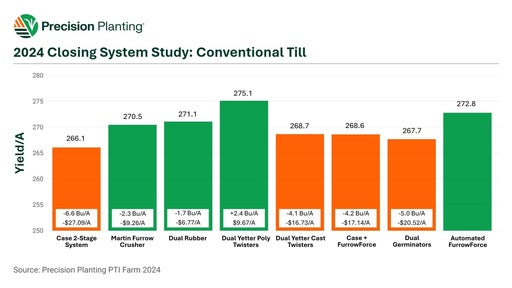

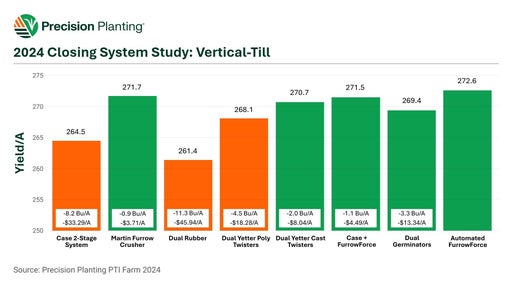

The main goal of a proper closing system is to remove air pockets, lift and fracture the side walls to achieve good seed-to-soil contact. In this study, we evaluated the performance of non-sensing single-stage and two-stage automatic sensing closing systems in four different tillage practices:

- Conventional » In the fall after harvest, deep 13” ripping with aggressive cutting and mixing of residue. A spring soil finisher leveled before planting.

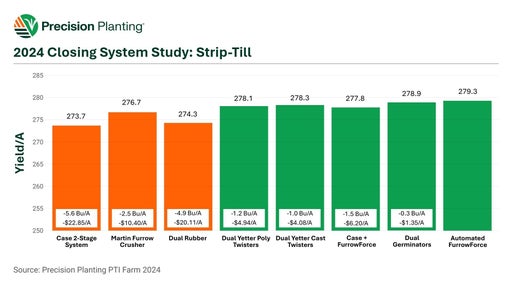

- Strip-Till » In the fall after harvest, 10” deep strips were created with a strip-till unit. Herbicide was used as a burndown to control early season weeds in the absence of spring tillage.

- Vertical-Till » In the fall after harvest, vertical tillage was used to mix, cut, and level residue in a 3” depth tillage pass. Herbicide was used as a burndown to control early season weeds in the absence of spring tillage.

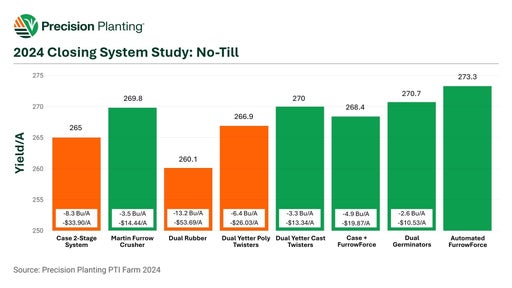

- No-Till » Planting directly into last year’s soybean stubble with no tillage activity performed. Herbicide was used as a burndown to control early season weeds in the absence of tillage.

Breaking it Down

Next, we weighed the pros and cons of each closing system we tested:

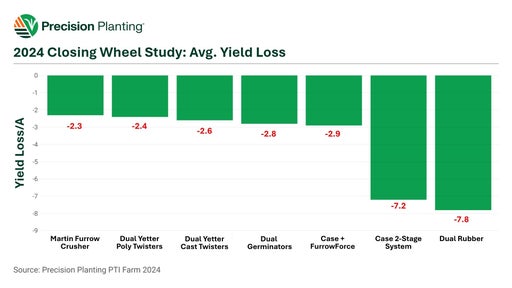

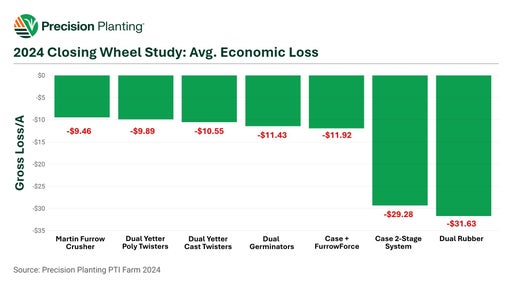

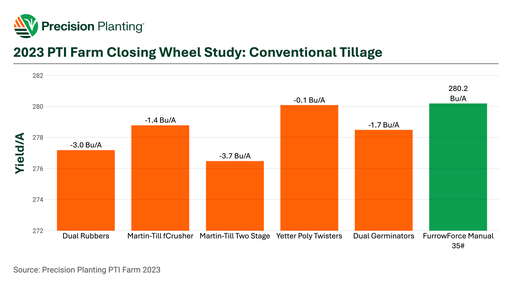

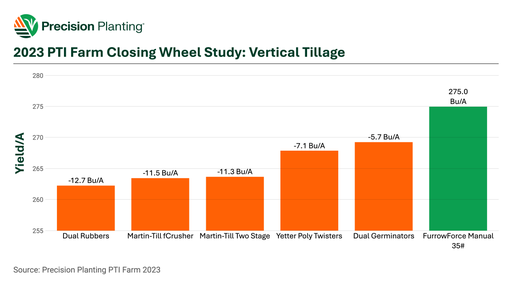

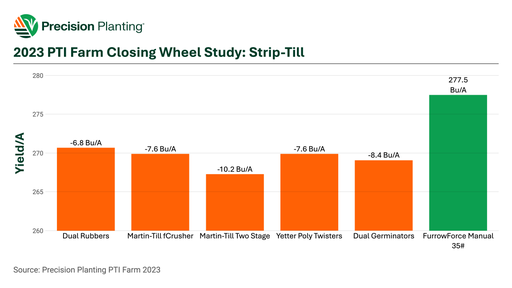

Study Results

The clear advantage for FurrowForce occurred in reduced tillage environments such as no-till and vertical tillage. In these programs, average yield gains of up to +4.5 to +6.0 Bu/A with increased revenue of +$18.16 to +$24.54/A clearly indicate that in tougher closing situations, a more robust system is needed to effectively close the furrow.

Overall, FurrowForce two-stage manual closing system resulted in average yield gains of +3.9 Bu/A and additional revenue of +$16.31/A across all tillage environments.

Past Study Videos

InsidePTI S4•E10

Closing Wheel System Testing ‣ Corn

InsidePTI S2•E27

Closing Systems ‣ Corn

InsidePTI S1•E05

Closing the Furrow - Part 1

InsidePTI S1•E06

Closing the Furrow - Part 2

InsidePTI S1•E55

Closing Systems Trial

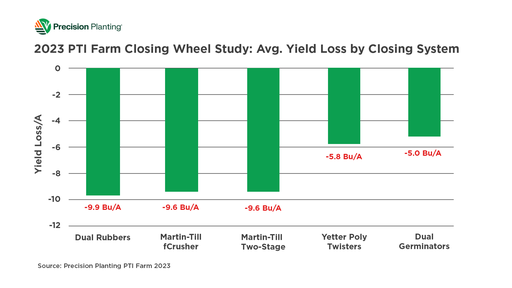

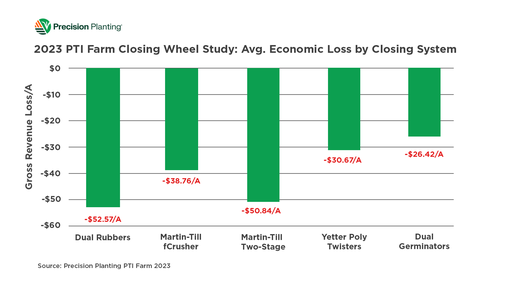

Past Study: 2023

In our 2023 study results, FurrowForce had average yield gains of 6.66 Bu/A across all tillage environments, which equated to additional revenue of $32.94/A.

However, the most significant advantage for FurrowForce occurred in reduced tillage environments such as no-till and vertical tillage. In these programs, FurrowForce had average yield gains of up to 10.3 Bu/A with increased revenue of $54.48/A. This clearly indicates that when it comes to tougher closing situations, a more robust system is needed to effectively close the furrow and protect our yield.

Study Details

Study data collected 2018-2024 at the PTI Farm in Pontiac, IL.

| Planting Date | 2024 - May 11 2022-2023 - May 11 2021 - April 27 2018-2020 - May 5 | Rotation | CAB, CAC (2018) |

| Row Width | 30" | Population | 36K |

| Corn Prices | 2024 - $4.08 2023 - $5.31 2022 - $6.00 2021 - $5.00 2020 - $3.75 2019 - $3.67 2018 - $3.50 | Hybrid | 2024 - Wyffels 6886 VTDP 2023 - DKC 59-82VTDP 2022 - DKC 59-82 2021 - Integra 6342 2020 - DKC 65-95 2019 - Wyffels 5818RIB 2018 - Wyffels 7696VTPro |