HeadSight | Grain

Automatic grain header height control

Equipped for

Automatic Grain Header Height & Tilt Control

OEM and aftermarket solution for grain headers.

Capture Yield and Decrease Fatigue

Long days in the combine cab are exhausting, especially when navigating challenging terrain and harvesting damaged crops. With automatic header height and tilt control, you can maximize your crop's harvest with minimum stress. Let HeadSight do the calculating and adjusting for you.

Upgrade Your Standard Control

Even if your grain head comes standard with height control, the performance isn't as accurate as HeadSight. You can swap out the OEM system for HeadSight's superior control system.

Sensors

Poly Arm Sensors

Three mounting styles to accommodate different headers and ground conditions.

Standard

The versatile and robust Standard sensor design mounts just behind the cutter bar for flex and draper headers. Header specific mounting brackets are available for most popular header models.

Terrace

The narrow profile of the Terrace sensor mounts in front of the header on the crop dividers – giving the combine an even earlier warning of changes in ground conditions. The Terrace sensor system is recommended for challenging terrain or high harvesting speeds.

Low-Pro

The compact low-profile sensor mounts directly under the cutter bar using the existing cutter bar guard bolts. This mount allows a header control option, even for challenging, rigid cutter bar configurations.

Control

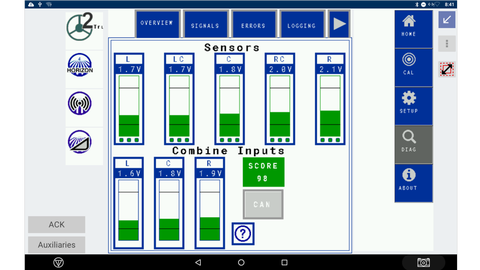

HeadSight Control System

Upgrade the VT present in your combine cab.

HeadSight provides superior performance for your header height control system, reliability and integrated header functions to the in-cab virtual terminal interface.

Featuring:

- Automatic calibration

- In-cab monitoring and control of header functions

- Supports up to 7 height sensors

Feathersight Software

Precision feathering for rigid cutter bars.

On standard grain header height control systems there are 2 modes for control - standard (using height sensors) or float mode. But neither allow you to run header height control near or lightly on the ground.

The solution? Feathersight reads the header height sensors and the feeder house lift cylinder pressure to control the header and float it on the ground. Feathersight allows you to run the header on the ground up to fifteen inches off the ground.

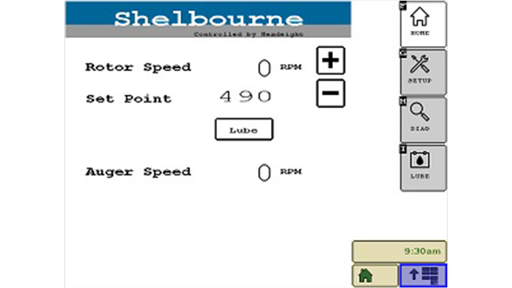

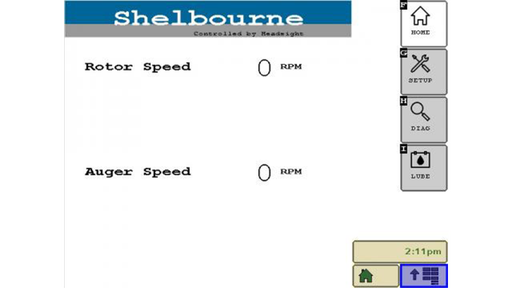

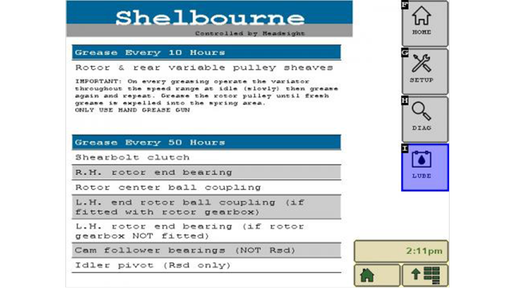

Shelbourne App

We've partnered with Shelbourne to offer an app for grain headers, allowing in-cab monitoring and control of header functions from the combine VT. Gain the following metrics:

- Control Header Rotor Speed

- Eliminates need for factory Shelbourne display

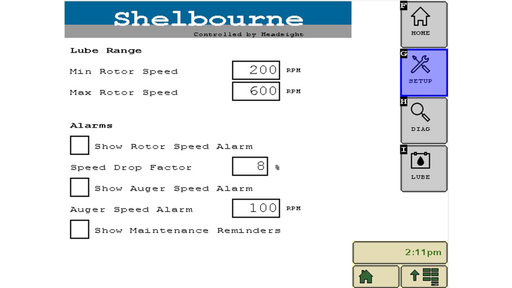

- Rotor and Auger Speed – displays speed and set alarms for high/low speed warnings

- Lube – cycles rotor through speed range after greasing

- Maintenance Reminders – displays maintenance reminders for header

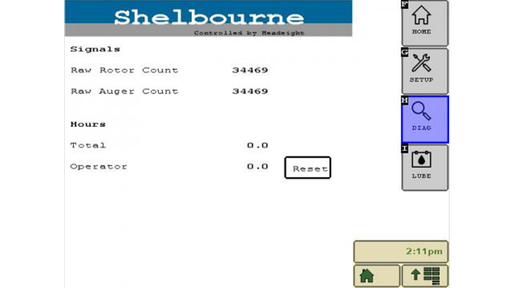

- Header Hours – logs hours when header is engaged

We purchased the HeadSight control system because we wanted to increase harvest time while not damaging the header, the system installed easily and we are very pleased with the results.

Mike Carefoot

Swift Current, Saskatchewan

HeadSight Product Resources

Download product manuals, software updates, and more.