Ready Row Unit

Don't trade planters—upgrade what you already own

Equipped for

Why buy a ready row unit?

Don’t Trade Planters

Upgrade what you already own.

Spend Money on What Makes You Money

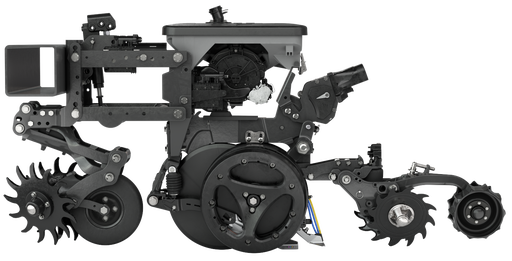

When many farmers trade planters, the goal is to get an updated row unit that doesn’t need maintenance this season while also updating to the latest technology. Typically the toolbar of the planter is in great shape. What if you could get the updated row unit and technology you want, without the expense and hassle of trading planters? The Precision Planting Ready Row Unit solves both issues: replace your current row units with a retrofit row unit and then build on that row unit with the latest technology.

Customized to Your Farm

This row unit upgrade allows you to take your current planter, remove the row units, and add new row units that are ready to be equipped with the technology and systems that you desire. You have the ability to work with a Precision Planting Premier Dealer to customize your planter to your needs with different gauge wheels, closing systems, row cleaners, and of course the Precision Planting technology to make your newly built planter maximize each seed.

Why Calibration Matters

Depth Matters

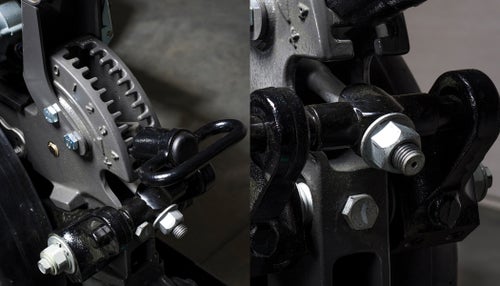

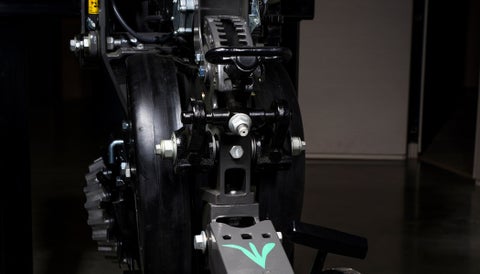

Consistent planting depth is critical to uniform emergence and stand establishment. Mechanical variation in the manufacturing process and wear on disk openers and the depth adjustment linkage can all lead to planting shallower than the depth setting. The Precision Planting Ready Row Unit features a depth calibration system which allows every row unit to be calibrated to the same depth before going to the field.

This photo illustrates the emergence variation between two rows of the same planter set at the same depth setting but with true planting depths varied by 5/8” between rows.

How Depth Calibration Works

The calibration system ensures that the Precision Planting Ready Row Unit has every row planting consistently before going to the field. A simple mechanism on the row-unit allows you to turn a lock nut to get the depth true; once that is complete, you have confidence all season long that the depth you have set the row-unit at is the depth it is planting.

Row Unit Specs

- Cast Iron Row Unit

- 14” Parallel arms

- 16” Disk openers

- 11” of row-unit travel

- Gauge wheel options: 3” or 4.5”

- Optional gauge wheel scrapers

- Closing wheel options: rubber, cast iron, or none (add aftermarket)

- Universal faceplate: many row cleaner and fertilizer coulter options

Manufactured in AGCO’s Beloit, KS factory, a state of the art facility which is ISO 9001 certified for meeting strict quality standards.

Product Resources

Ready Row Unit Resources

Download installation and assembly guides here!